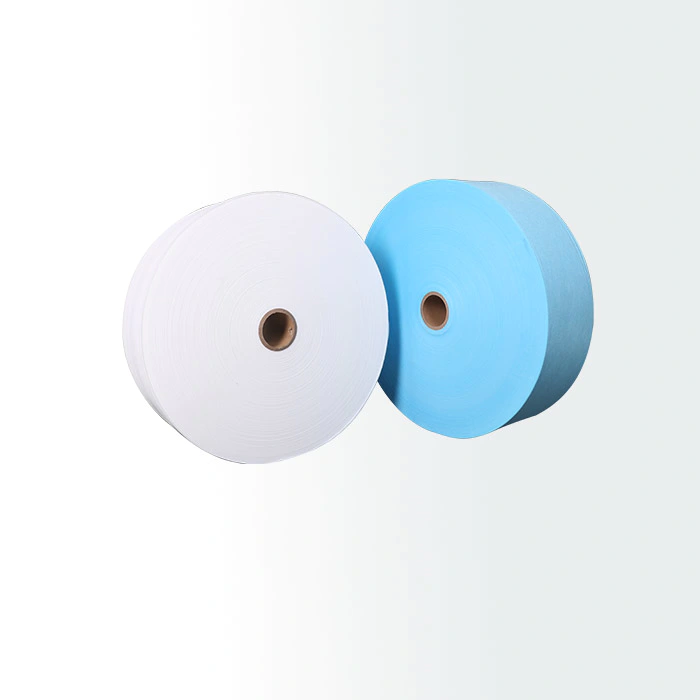

- PP spunbond nonwoven fabric

- SS nonwoven fabric

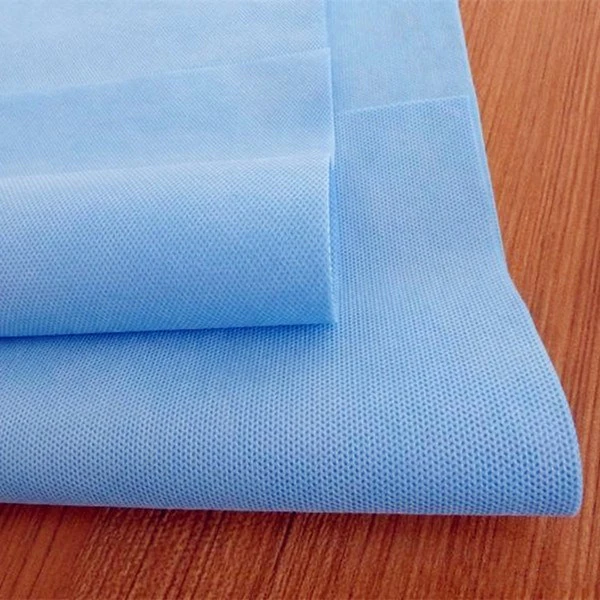

- Medical Nonwoven Fabric

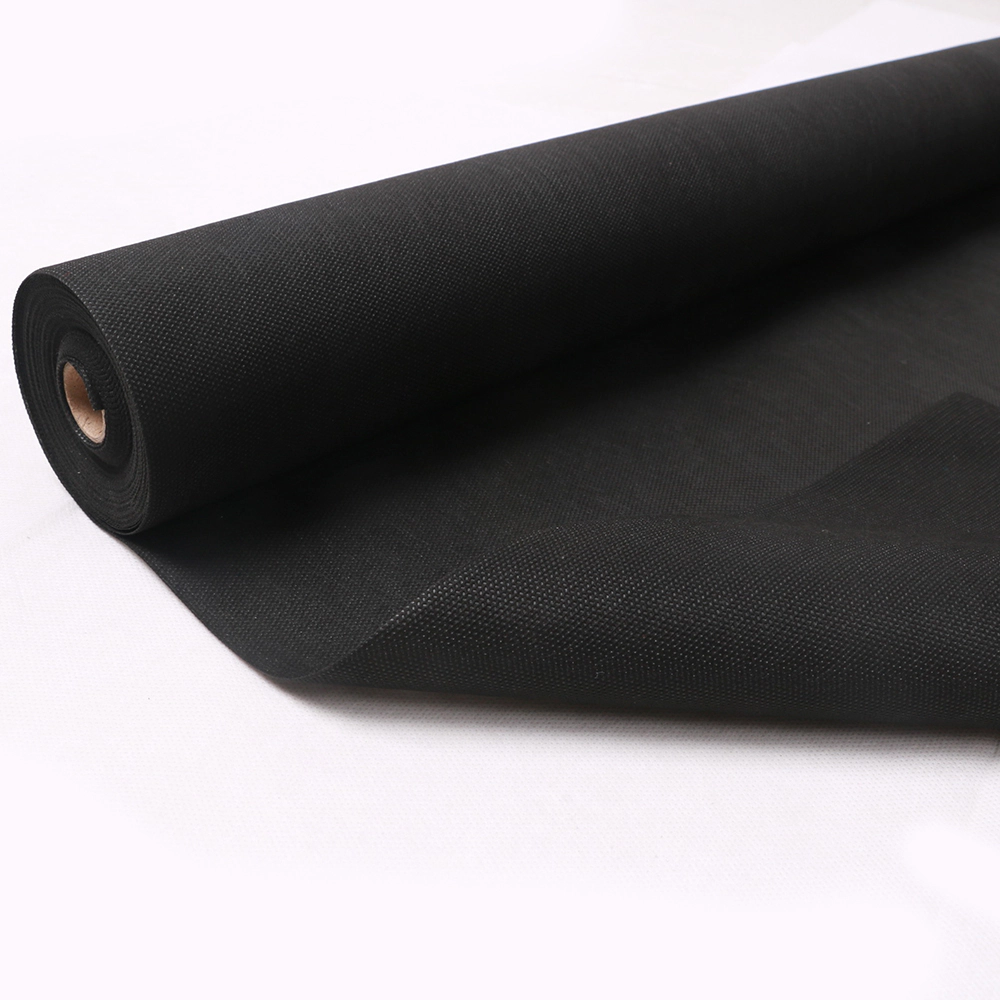

- Furniture upholstery nonwoven fabric

- Agricultural / Gardening nonwoven fabric

- Nonwoven Tablecloth

- Non woven packaging

- Nonwoven finished products

- SMS nonwoven fabric

- Meltblown nonwoven fabric

- Needle punched nonwoven fabric

- Spunlace nonwoven fabric

how to make non woven fabric

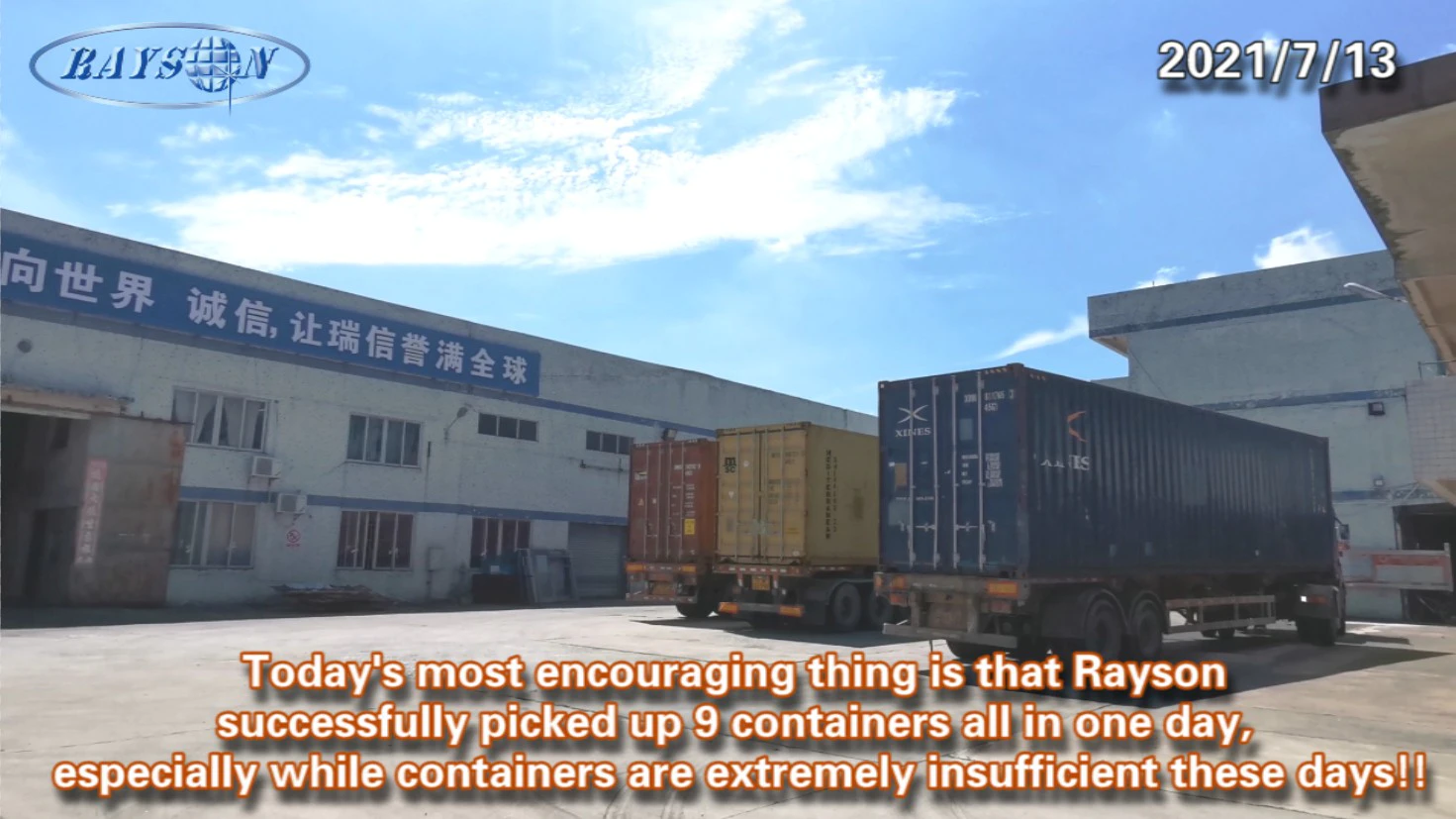

.

Non-woven fabric has multiple uses, from personal protective equipment to upholstery, and it's relatively easy to produce. This guide will cover the essential steps to create it, and some of the applications of this versatile material.

Overview: What is Non-Woven Fabric

Non-woven fabric is any material that doesn't require weaving, doesn't have a conventional yarn or thread structure, and hasn't been bonded with chemical adhesives. Instead, it's made of fibers that are mechanically intertwined, sometimes with help from thermal or chemical processes. These fibers can come from natural or synthetic sources, and the resulting fabric can have different properties depending on the production method.

Step 1: Fiber Selection

The first step to make non-woven fabric is choosing the right type of fiber, depending on your desired properties. Some examples include:

- Cotton: absorbent, soft, and hypoallergenic.

- Polyester: durable, heat-resistant, and lightweight.

- Rayon: breathable, drapes well, and often used in blends.

- Nylon: strong, elastic, and versatile.

You can also use recycled materials, like shredded plastic bottles or denim fibers, if you're aiming for sustainability.

Step 2: Carding

Carding is a process where the selected fibers get cleaned, aligned, and turned into a fluffy mass. It's an essential step to ensure the fibers blend well and create a uniform base for the next phases. Carding machines have numerous fine-toothed rollers that comb the fibers in different directions, disentangling any knots or clumps that could weaken the final product.

Step 3: Laying

Laying, also known as web forming, is the stage where the fluffy mass of fibers gets placed on a moving conveyor belt or drum. The fibers should be spread evenly and compacted to form a thin layer of the desired thickness. There are different types of laying machines, depending on the method used to achieve the compaction:

- Air-laid: uses pressurized air to arrange the fibers in a random pattern.

- Wet-laid: adds a water-based binder to the fibers to create a cohesive structure.

- Dry-laid: uses mechanical needles to punch the fibers and create a denser web.

Each method has its advantages and drawbacks, but all of them lead to a non-woven fabric that's more absorbent, breathable, and flexible than a traditional woven fabric.

Step 4: Bonding

Bonding is the process of fusing the fibers in the laid web to create a stable fabric. There are different bonding techniques to choose from:

- Thermal: applies heat to melt the fibers or a bonding agent added to them.

- Chemical: uses a liquid or gas adhesive that sticks the fibers together when they dry.

- Mechanical: uses needles, water jets or ultrasonic waves to interlock the fibers without using chemicals or heat.

The bonding technique you choose will depend on the final use of the non-woven fabric. For example, if you want to create disposable medical gowns or face masks, you'll need a material that's both lightweight and resistant to fluid penetration. In that case, a combination of air-laying and thermal bonding might be the best choice.

Applications of Non-Woven Fabric

Non-woven fabric is ubiquitous in many industries and products, from baby diapers to car interiors. Here are some of the most common applications:

- Hygiene products: non-woven fabric is used to make wipes, sanitary napkins, and incontinence pads.

- Agriculture: non-woven fabric can protect crops from pests or serve as a cover for greenhouses.

- Furniture: non-woven fabric is used as upholstery, cushioning, or lining material.

- Packaging: non-woven fabric can be made into bags, filters, or insulation materials.

- Construction: non-woven fabric can replace or reinforce traditional building materials, like asphalt or concrete.

In Conclusion

Making non-woven fabric is a relatively simple process that involves selecting fibers, carding them, laying them, and bonding them. The resulting material can have multiple properties, depending on the production method and the intended use. Non-woven fabric is an essential part of many products in various industries, and its versatility and eco-friendliness make it a popular choice among manufacturers and consumers.