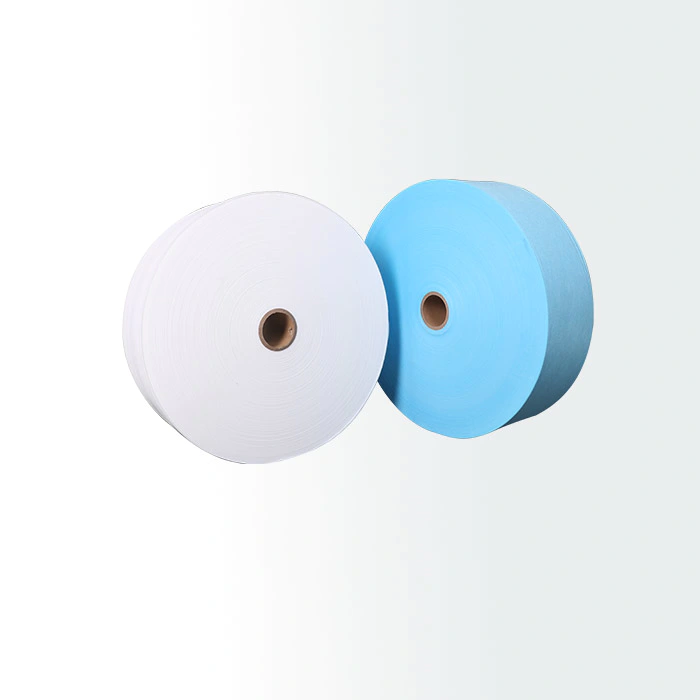

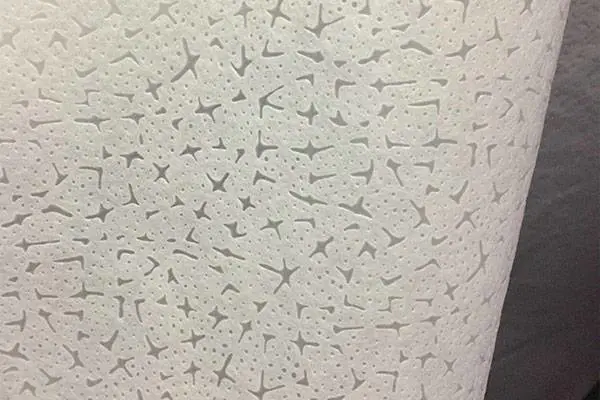

- PP spunbond nonwoven fabric

- SS nonwoven fabric

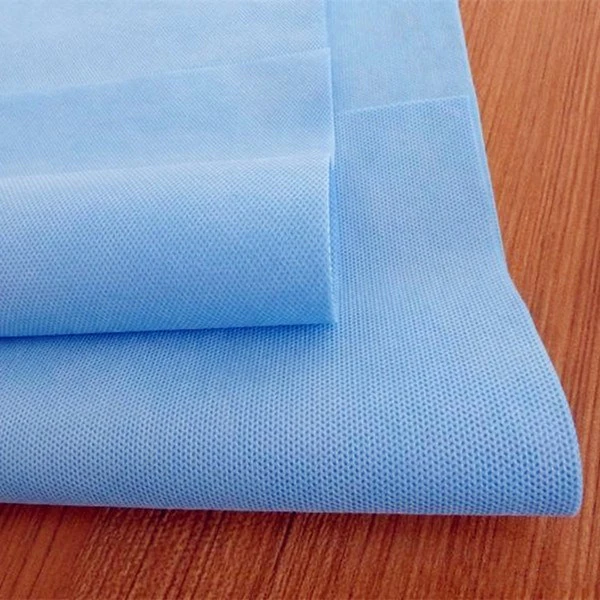

- Medical Nonwoven Fabric

- Furniture upholstery nonwoven fabric

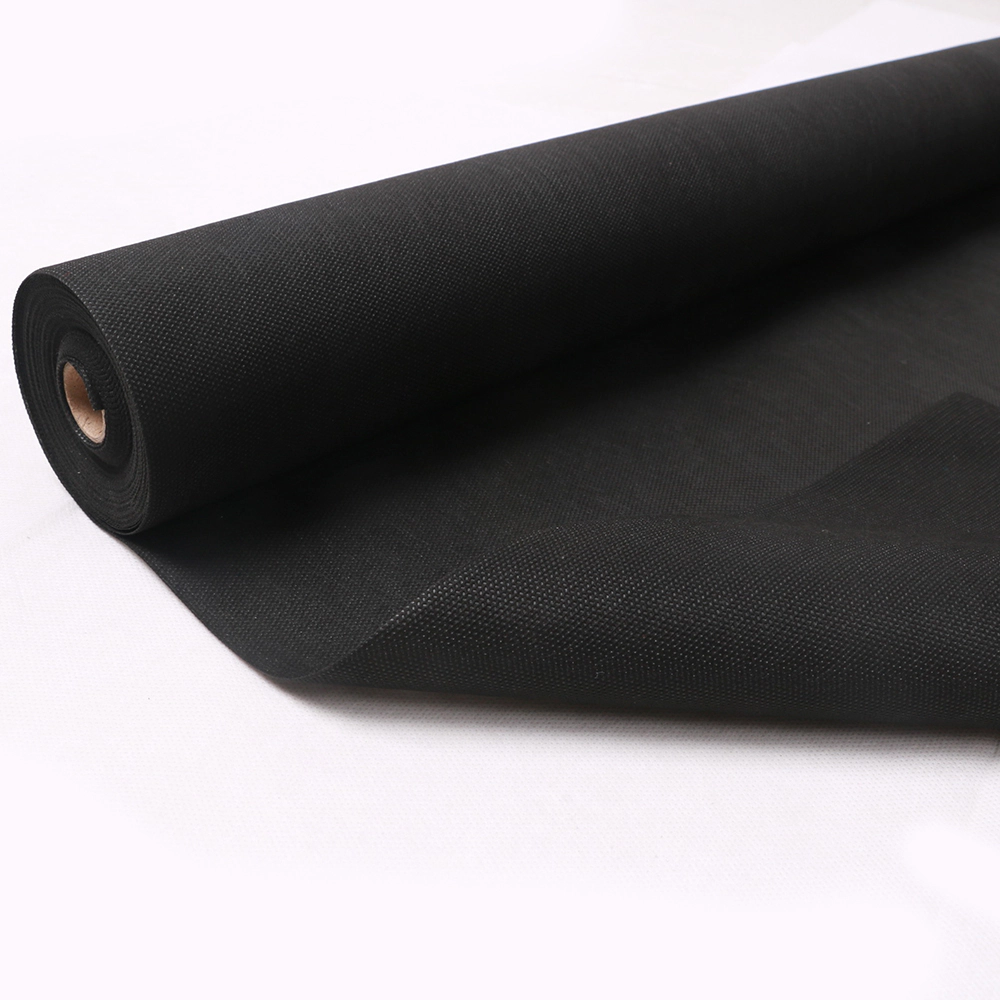

- Agricultural / Gardening nonwoven fabric

- Nonwoven Tablecloth

- Non woven packaging

- Nonwoven finished products

- SMS nonwoven fabric

- Meltblown nonwoven fabric

- Needle punched nonwoven fabric

- Spunlace nonwoven fabric

18 Pp Spunbond Non Woven Fabric Ideas

Melt-blown fabrics are created from steady polypropylene microfibers and is used in composite buildings of many kinds of facemasks due to its excessive filtration efficiency and repellency. Spun-bond/thermal bond fabric is typically created from polypropylene in a comparatively open structure and is utilized in bouffants and shoe covers.

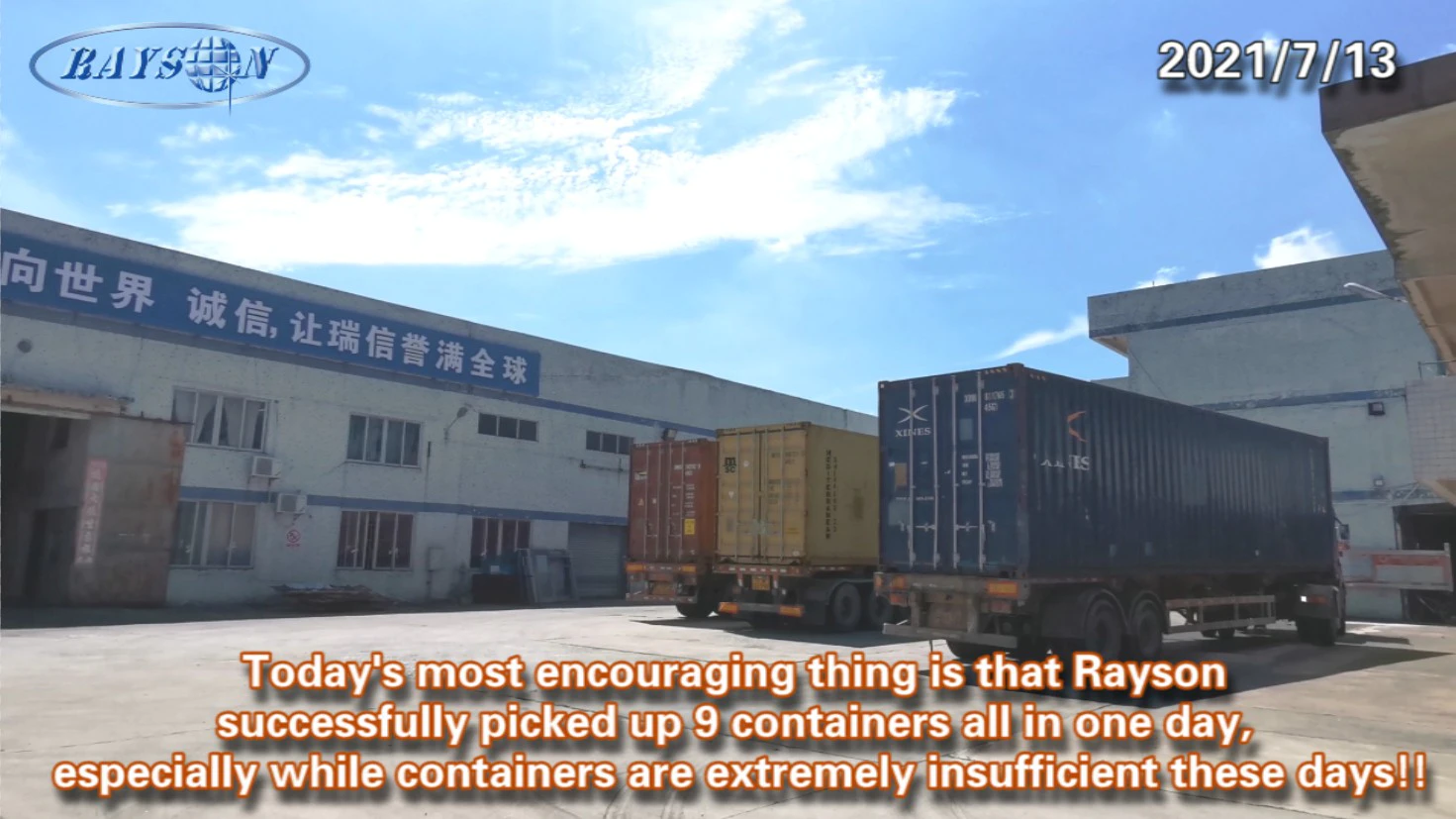

These merchandise might end in important financial savings due to the flexibility to do brief runs and provide mass-customization like by no means earlier than. The proper type of nonwoven structure would be a perfect candidate for such printed materials. Across differing polymer chemistries, environmental situations and floor properties, the company is ensuring manufacturers have the UV stability their base supplies need to succeed in the marketplace.

For occasion, in December 2017, Arvind Ltd. and OG Corporation of Japan entered into a three way partnership for manufacturing and trading specialized supplies. Melt-blown fabrics are created when a polymer melt is extruded through small nozzles surrounded by high speed blowing fuel. As a result, the randomly distributed fibers type a non-woven sheet product.

These materials don't show high barrier efficiency such as excessive filtration effectivity or splash resistance and subsequently have limited use in crucial environments. However, spun-bond fabrics are made from continuous filaments, which enhance energy and supply sufficient barrier properties for much less crucial environments. With technical observe up and continuous analysis, we are in a position to produce an exceptional assortment of PP Spunbonded Nonwoven Fabric. These materials are designed from PP at our state of the art machining facility, as per the requirements laid down by regulatory our bodies. Our PP Spunbonded Nonwoven Fabric is suitable for designing napkins, diapers and medical disposables like coverall, suits, face masks & hoods. In addition, we provide these materials in qualitative packaging to keep away from injury throughout transportation.

Hand selecting is advantageous compared to machine selecting, as solely fibers from fully mature capsules are being collected. Among the plant-derived fibers, cotton has the best proportion of cellulose and is free of wood particulates [1-4,6]. According to the Australian Institute of Health and Welfare, urinary incontinence affects 37% of ladies and 13% of men in Australia. Most of the consumers in India are not conscious of adult incontinence merchandise. The major cause is lack of promotional activities and advertisements by varied manufacturers. Additionally, limited availability of those products in India in comparison with other hygiene products is likely to prohibit grownup incontinence within the polypropylene nonwoven materials market. Rapid technological advancements and innovations on this field, such as design of nonwoven fabrics with skincare and softness, have additional led to the polypropylene nonwoven fabrics market progress.

Macro developments in sustainability will drive main new product and process improvements in nonwovens. Also, new developments in durable nonwovens might emerge as the next era of technical textiles for a lot of important applications. These buildings are additionally robust, and possess significantly higher floor area than present fabrics that will enable functionalities that aren't obtainable right now. Microfiber nonwovens are utilized in suede and leather products, durable wipes and automotive components corresponding to headliners, however have made little headway in sturdy, washable, technical clothing applications. This is partly as a result of microdenier materials up to now have lacked sufficient drape and stretch, and are difficult to dye — they can not produce deep shades. This could lead to the replacement of multicolored woven fabrics made using multicolored yarns with simple woven fabrics that may be printed to imitate the finer buildings.