Disposable bed sheet is made from hydrophobic material and designed for optimal protection for patients.

NON WOVEN MEDICAL PRODUCTS

| Product: | Disposable hospital bedsheet non woven fabric |

| Raw material: | 100% new imported polypropylene |

| Technics: | Spunbond process |

| Weight: | 9-150gsm |

| Width: | 2-320cm |

| Colors: | Different colors available |

| MOQ: | 1000kgs |

| Packaging: | Seaworthy transparent polybag |

| Characteristics: | Made from 100% polypropylene |

| Width: can be cut into any width within 3.2m | |

| Soft feeling, eco friendly, non toxic, recycleable, breathable | |

| Good strength and elongation | |

| Anti bacteria,UV stablized,flame retardant processed | |

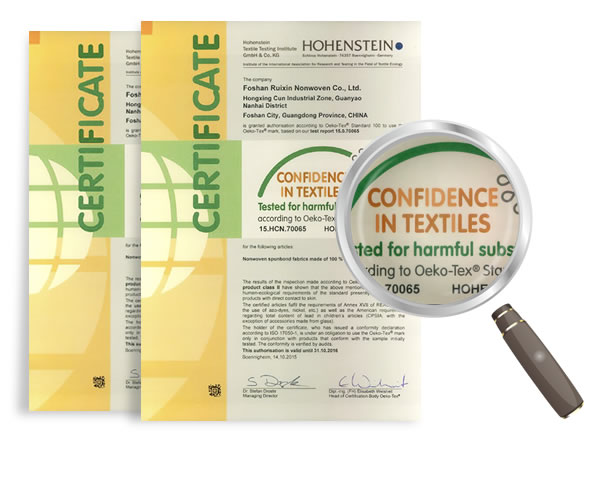

| SGS & IKEA & Oeko &Tex certified | |

GOODS USAGE

SHIPPING & PAYMENT TERMS

Roll length: as per your requirements.

Package: 25pcs/bags 300pcs/carton.

Mini order: 1 Ton/color.

Payment: TT 30% Deposit, against BL copy, pay the balance. or L/C at sight.

Delivery date: 2weeks after receive your deposit.

PRODUCTION & PACKING

|

PACKING DETAILS | |

|  |

CHARACTERISTIC

---------- Eco-friendly, water repellent

---------- Can have anti-UV(1%-5%), anti-bacteria,anti-static,flame retardant function as request

---------- Tear resistant, shrink-resistant

---------- Strong strength and elongation, soft, non-toxic

---------- Excellent property of air through

COMPANY ADVANTAGES

1. Saving your time

We have strong production capcity and R& D team, saving your time for you to catch selling season.

There are 6 production lines for p.p.nonwoven fabric with monthly output up to 1300 tons.

The width of the 6 production lines is as below: one of them is 2.4m, specially produce SS non woven fabric, two lines are 3.2m, two lines are 2.4m, and the last one is 2m.

There are 5 automatic cutting machines for non woven finished table cloth which can produce 200 tons monthly.

There are 5 advanced equipments for other non woven finished products. We make 100 tons of small roll non woven fabric and 200 tons of joint non woven with glue.

2. Best service

Our sales team are quite familiared with international trade. We attend many fairs show home and abroad. And use different netword platform to explore international market

3. Competitive price

We have sufficient raw material and offer stable price to guarantee the benefit of both sides and reduce the risk of trade.

4. Relieved to buy

We have a complete quality management system and obviously competitive price. 95% of our product which can meet the requirement of different fields are exported to more than 30 countries. We have established business relationship with some world-famous brands.

OEKO-TEX® Standard 100

5. Purchasing safety - improving

The OEKO-TEX® Standard 100 is and independent testing and certification system for textile raw materials, intermediate and end products at all stages of production. Examples for items eligible for certification: all types of clothing, domestic and household textiles, bed linen, terry cloth items, textile toys and more.

Copyright © 2021 by www.raysonchina.com All Rights Reserved Design by www.raysonchina.com Sitemap 粤ICP备19068558号-5

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist