Top Non-Woven Material Suppliers: Choosing The Best Partner For Your Business

In today’s fast-evolving market, selecting the right non-woven material supplier can make all the difference for your business’s success. Whether you’re in healthcare, apparel, automotive, or packaging, partnering with a reliable supplier ensures quality, innovation, and timely delivery—key factors that drive growth and customer satisfaction. In this article, we dive deep into the top non-woven material suppliers, offering you valuable insights and practical tips to help you choose the best partner that aligns perfectly with your unique business needs. Read on to discover how to elevate your operations with trusted suppliers who deliver excellence every step of the way.

- Understanding the Importance of Selecting the Right Non-Woven Material Supplier

In today’s competitive manufacturing landscape, non-woven materials play a critical role across a diverse range of industries, including healthcare, automotive, construction, hygiene products, and packaging. As the demand for specialized and high-quality non-woven fabrics increases, choosing the right non woven material suppliers becomes an essential decision that can significantly impact the overall success of a business. Understanding the importance of this selection process helps companies build reliable supply chains, maintain product quality, and drive innovation.

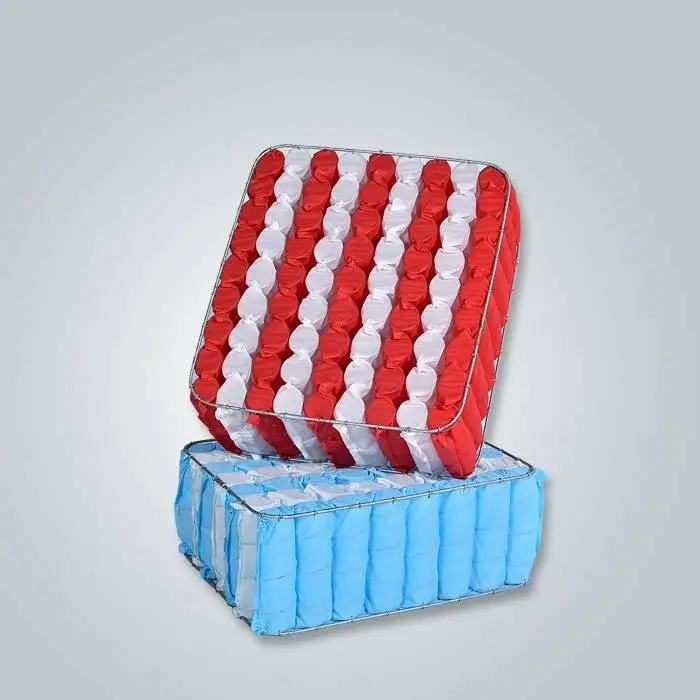

Non-woven materials are engineered fabrics made from fibers bonded together by chemical, mechanical, heat, or solvent treatment, without weaving or knitting. These materials’ unique characteristics—such as high absorbency, durability, softness, and resistance to bacteria or chemicals—make them indispensable for many applications. Companies rely heavily on their non woven material suppliers to provide materials that meet strict specifications and regulatory standards. Therefore, the supplier’s capability to consistently deliver high-quality products strongly influences a manufacturer's ability to fulfill customer expectations and regulatory compliance.

One of the main reasons why selecting the right non woven material supplier is crucial involves quality assurance. A dependable supplier ensures that the non-woven fabrics meet specific criteria such as weight, thickness, fiber composition, and performance attributes like absorbency or filtration efficiency. If the material quality fluctuates or fails to meet the required standards, the resulting products may suffer from defects, reduced functionality, or even regulatory rejection, leading to costly recalls and damage to brand reputation. Hence, companies should engage suppliers who have a robust quality management system, regular testing protocols, and certifications that guarantee their materials consistently meet stringent specifications.

In addition to product quality, the reliability of supply is a paramount consideration. Businesses that depend on non woven material suppliers must ensure uninterrupted access to materials to support their manufacturing processes. Delays or shortages can stall production lines, delay deliveries, and erode customer trust. Therefore, it is imperative to partner with suppliers who have strong manufacturing capacity, transparent inventory management, and responsive logistics. This ensures that orders are fulfilled on time, even when demand fluctuates, and that contingency plans are in place during supply chain disruptions.

Cost-effectiveness also plays a vital role in supplier selection. While prioritizing quality is crucial, businesses must balance performance with cost to maintain competitive pricing. The right supplier offers competitive pricing structures without compromising on material integrity. Moreover, they may provide value-added services such as material customization, technical support, and flexible ordering options. These services can improve efficiency and reduce costs associated with waste, rework, or inventory holding. Working closely with suppliers who understand your business goals allows for tailored solutions that optimize both cost and quality.

Another essential factor is the supplier’s commitment to sustainability and innovation. As environmental concerns grow globally, many industries are seeking eco-friendly alternatives and sustainable sourcing practices. Forward-thinking non woven material suppliers invest in developing biodegradable, recyclable, or renewable materials and adopt green manufacturing processes that minimize waste and environmental impact. Partnering with such suppliers not only helps companies meet their sustainability commitments but also positions them as responsible and innovative players in their markets. Moreover, access to cutting-edge materials and technologies through supplier collaboration can provide a competitive advantage by enabling the development of superior products with enhanced performance features.

Communication and partnership quality should not be underestimated either. The best non woven material suppliers function as true partners, providing expert advice, proactive problem-solving, and transparent communication throughout the lifecycle of the collaboration. This relationship enables businesses to anticipate challenges, adapt to market changes, and co-develop new material solutions tailored to evolving needs. Suppliers who prioritize customer service and maintain open lines of dialogue help build long-term trust and mutual growth.

In conclusion, the importance of selecting the right non woven material suppliers cannot be overstated. From assuring consistent quality and reliable delivery to balancing cost, advancing sustainability, and fostering innovation, the choice of supplier deeply influences a company’s product quality, operational efficiency, and market competitiveness. Companies that invest time and effort in thoroughly evaluating potential non woven material suppliers—including auditing their capabilities, certifications, financial stability, and customer reviews—position themselves for success in a demanding global marketplace.

- Key Criteria to Evaluate Non-Woven Material Suppliers

**Key Criteria to Evaluate Non-Woven Material Suppliers**

Choosing the right non woven material suppliers is a critical step for businesses involved in manufacturing, packaging, medical products, hygiene goods, and various other applications that rely on non-woven fabrics. The performance, quality, and reliability of the non-woven materials you source directly impact your product’s success, cost-efficiency, and reputation. Consequently, evaluating potential suppliers with a well-rounded, strategic approach is essential. This detailed overview explores the key criteria businesses should consider when assessing non woven material suppliers, ensuring a partnership that supports growth and product excellence.

**1. Quality Assurance and Certifications**

Quality is paramount when choosing non woven material suppliers. High-quality materials ensure durability, functional performance, and compliance with industry standards. Begin your evaluation by reviewing the supplier’s quality assurance process. This includes understanding their production techniques, quality control checks, and testing protocols. Ask for relevant certifications such as ISO 9001 for quality management, ISO 13485 if you are in medical applications, or OEKO-TEX Standard 100, which certifies textiles free from harmful substances.

Reputable suppliers will readily provide test reports and sample materials for your inspection. Assessing quality not only guarantees a superior end product but also minimizes risks related to defects, returns, or regulatory non-compliance.

**2. Range and Specialization of Non-Woven Materials**

Non-woven materials come in various forms—spunbond, meltblown, needle-punched, hydroentangled—each suited to specific uses. An ideal non woven material supplier offers a broad product portfolio catering to different industry needs and customization capabilities.

Evaluate whether the supplier can supply materials that meet your unique specifications such as weight, thickness, permeability, strength, and texture. Suppliers with in-house R&D teams or technical support can also help innovate or tailor materials to optimize your products. Specialized suppliers with expertise in your field of use may better understand your challenges and quality requirements.

**3. Production Capacity and Lead Time**

Supply chain reliability depends heavily on a supplier’s production capacity and ability to meet delivery schedules. Confirm the supplier’s manufacturing output capability, especially if your business demands large or recurring volumes.

Discuss typical lead times for orders and the supplier’s flexibility in handling rush or scaled-up orders. Suppliers with multiple production lines, advanced machinery, and efficient logistics systems generally provide more dependable and consistent supply, reducing the risk of production downtime on your end.

**4. Cost and Pricing Structure**

Price competitiveness is a key factor but should be evaluated holistically alongside quality and service. Obtain detailed quotations clarifying the pricing structure, including base price per unit, volume discounts, packaging costs, shipping fees, and potential tariffs.

Negotiating transparent pricing terms helps avoid unexpected expenses later. Be cautious of suppliers offering significantly lower prices that may compromise on quality, sustainability, or service. Consider the total cost of ownership to ensure the material aligns with your budget without sacrificing standards.

**5. Sustainability and Environmental Compliance**

Sustainability considerations are increasingly crucial when selecting non woven material suppliers. Many end consumers and regulatory bodies demand environmentally responsible sourcing.

Evaluate whether the supplier uses recycled or bio-based fibers, implements waste reduction in production, and adheres to environmental regulations. Certifications like Global Recycle Standard (GRS) or OEKO-TEX can validate sustainable claims. Prioritizing suppliers committed to eco-friendly practices supports your company’s ethical values and appeals to conscious consumers.

**6. Supply Chain Transparency and Traceability**

Understanding the origin and journey of your non-woven materials enhances trust and risk management. Suppliers who offer transparency in their supply chains—disclosing raw material sources, manufacturing locations, and transport arrangements—add value by ensuring compliance with labor laws and ethical standards.

Traceability also aids in quickly addressing quality issues or recalls, safeguarding your brand reputation.

**7. Customer Service and Technical Support**

Effective communication and support are vital in a supplier partnership. Evaluate the responsiveness, knowledgeability, and problem-solving ability of the supplier’s representatives.

A supplier providing dedicated account managers, technical advice, and on-site assistance facilitates smoother operations and product development. Prompt resolution of issues and proactive updates about order status can significantly influence your satisfaction and operational efficiency.

**8. Reputation and Industry Experience**

Finally, consider the supplier’s reputation within the industry. Established non woven material suppliers with verifiable track records of consistent performance and positive client feedback demonstrate stability and reliability.

Seek references or case studies relevant to your application. Suppliers who have served leading brands or complicated projects may be better equipped to meet high standards.

Choosing the best non woven material suppliers involves a comprehensive analysis of quality, capacity, cost, sustainability, and support. Businesses that rigorously apply these criteria position themselves to form strong partnerships that drive innovation, efficiency, and competitiveness in the marketplace.

- Leading Non-Woven Material Suppliers in the Market Today

In today’s rapidly evolving industrial landscape, finding reliable non woven material suppliers is crucial for businesses looking to maintain a competitive edge. Non-woven materials have become indispensable across various sectors, including healthcare, agriculture, automotive, construction, and hygiene products, due to their versatility, durability, and cost-effectiveness. As demand continues to grow, the market has seen a surge in leading suppliers who offer innovative products, customized solutions, and superior service. Understanding who these top players are and what sets them apart can help businesses choose the best partner to meet their specific needs.

Non woven material suppliers have adapted to the ever-expanding application areas by investing heavily in research and development to deliver advanced fabric technologies. These companies provide a wide range of products, from spunbond and meltblown fabrics to needlepunch and hydroentangled materials. High-quality suppliers differentiate themselves by ensuring consistent product quality, compliance with international standards, and the ability to scale production to meet large-volume demands.

One of the most recognized categories of non woven material suppliers today are those specializing in medical and hygiene fabrics. Given the critical role of these materials in manufacturing surgical masks, gowns, diapers, and wipes, suppliers in this domain prioritize antimicrobial properties, breathability, and softness. Leading suppliers integrate cutting-edge filtration technologies and sustainable raw materials, aligning their offerings with the increasing global push toward eco-friendly products.

Another vital sector where non woven material suppliers excel is agriculture. Suppliers delivering geotextiles and crop covers contribute significantly to soil stabilization, weed control, and moisture retention. These materials not only improve crop yield but also provide a more sustainable approach to farming. The top suppliers offer customized product weights, thicknesses, and UV resistance levels tailored to specific regional agricultural conditions, thus enabling farmers to maximize efficiency.

In the automotive and construction industries, non woven material suppliers have advanced the development of lightweight, sound-absorbing, and heat-resistant materials. These innovations address the growing demand for energy-efficient vehicles and sustainable building practices. Leading suppliers invest in cutting-edge manufacturing techniques such as spunlace and thermal bonding to produce materials that meet rigorous safety and performance standards.

What truly sets leading non woven material suppliers apart in today’s market is their commitment to customer collaboration. Many top suppliers offer co-development initiatives, allowing clients to tailor product characteristics such as tensile strength, permeability, and elasticity. This partnership approach ensures products are optimized not only for their intended use but also for cost-efficiency and ease of integration into existing manufacturing lines.

Sustainability has become another key differentiator among leading suppliers. With increasing regulatory demands and consumer awareness about environmental impact, reputable non woven material suppliers prioritize the use of recycled fibers, biodegradable polymers, and solvent-free manufacturing processes. Some suppliers have even pioneered closed-loop production systems to minimize waste and reduce carbon footprints. These initiatives resonate strongly with businesses intent on aligning their supply chains with broader corporate social responsibility goals.

Global reach and supply chain resilience are also critical factors when selecting a non woven material supplier. Leading suppliers have established multi-regional manufacturing facilities and diversified sourcing strategies to mitigate risks related to geopolitical tensions, shipping delays, and raw material shortages. Their robust logistics and inventory management systems ensure consistent delivery schedules, which is essential for businesses operating just-in-time production models.

In addition to product and operational excellence, many top-tier non woven material suppliers differentiate themselves by offering comprehensive technical support and training. They maintain teams of material scientists and engineers who advise clients on best practices for material handling, product design, and regulatory compliance. This level of expertise minimizes trial-and-error phases in product development and expedites market entry.

In conclusion, the best non woven material suppliers in the market today combine innovation, customization, sustainability, and reliable service to create value for their clients. Whether your business operates in healthcare, agriculture, automotive, or other industries reliant on non woven applications, choosing a supplier who understands your unique requirements and priorities is paramount. By partnering with a leading non woven material supplier, companies can ensure they have access to high-quality materials that support product performance, compliance, and long-term business growth.

- How to Assess Supplier Reliability and Quality Assurance

**How to Assess Supplier Reliability and Quality Assurance**

When your business depends on non woven material suppliers, selecting a reliable partner with strong quality assurance practices is critical for maintaining production efficiency and product integrity. Non woven materials find applications across diverse industries such as medical products, hygiene, automotive, filtration, and upholstery, making the quality and consistency of the supplies vital. However, with numerous suppliers in the market, how do you effectively assess their reliability and quality assurance capabilities? This article delves into key factors and strategies to evaluate potential non woven material suppliers, helping you forge partnerships that support your business goals.

**1. Evaluate Supplier Reputation and Track Record**

The first step in assessing supplier reliability is researching their market reputation and historical performance. Trusted non woven material suppliers often have a proven track record with existing customers, positive reviews, and case studies showing consistent delivery and product quality. To gauge this, seek testimonials from previous clients or request references. Suppliers willing to share performance data and customer feedback typically demonstrate their confidence and transparency, which are good indicators of reliability.

Industry certifications can also provide insights into supplier credibility. Certifications such as ISO 9001 for quality management, ISO 14001 for environmental management, or industry-specific standards like OEKO-TEX for textile safety imply adherence to stringent protocols. Such credentials show the supplier’s commitment to maintaining product standards and continual improvement, reducing the risk of quality lapses.

**2. Inspect Quality Control Systems**

Non woven material suppliers who invest in robust quality control systems are better positioned to deliver consistent, defect-free products. During your supplier evaluation, ask about their quality assurance processes. Do they employ regular inspections throughout production stages? Are raw materials tested on arrival for compliance with specifications? How do they monitor critical parameters like fiber composition, fabric weight, thickness, and tensile strength?

Leading suppliers often implement process control measures such as Statistical Process Control (SPC), wherein variations are monitored and addressed proactively to avoid deviations from quality standards. Additionally, understanding whether the supplier operates an in-house laboratory or collaborates with third-party testing agencies can highlight the thoroughness of their quality assurance.

Consider requesting sample batches to verify product attributes such as durability, texture, barrier properties (especially important for medical or hygiene applications), and chemical resistance. The ability to provide batch traceability is also crucial, as it allows you to track back any quality issues and manage recalls if necessary.

**3. Assess Delivery Performance and Supply Chain Stability**

Supplier reliability extends beyond product quality to encompass on-time delivery and uninterrupted supply chains. Even high-quality non woven materials lose value if they arrive late or in insufficient quantities. Therefore, evaluate the supplier’s logistics capabilities, lead times, and flexibility in meeting fluctuating order volumes.

Ask potential suppliers about their production capacity, stock management, and contingency plans for mitigating disruptions such as raw material shortages or transportation delays. Reputable non woven material suppliers often maintain buffer stocks and have strong relationships with raw material providers, enhancing supply chain resilience.

Performance metrics like on-time delivery rate and order accuracy can be requested or verified through customer feedback. Partners that communicate transparently about potential delays and proactively provide updates typically demonstrate higher reliability. Consider long-term contract options where stability is prioritized while allowing for periodic performance reviews.

**4. Review Technical Support and Customization Capabilities**

Reliability also involves how well the supplier supports your business needs, particularly if you require tailored non woven materials for specific applications. A reliable supplier offers technical consultation during product selection and customization, helping you optimize material properties such as weight, porosity, finish, or bonding techniques.

Review the responsiveness and expertise of their technical team. Prompt problem-solving and collaborative research efforts signal a supplier who values partnership beyond mere transactions. The ability to quickly adapt to changing requirements and implement quality improvements adds to overall supplier reliability.

**5. Understand Pricing Transparency and Contract Terms**

While cost should not be the sole determinant, clear pricing structures and fair contract terms are part of a trustworthy supplier relationship. Evaluate if the supplier is transparent about price components, including costs influenced by material grades, order volumes, and market conditions.

Confirm payment terms, warranty policies, and procedures for handling defective or non-compliant deliveries. Contracts that clearly define quality expectations and consequences for breaches help safeguard your interests and encourage supplier accountability.

---

In essence, thoroughly assessing the reliability and quality assurance practices of non woven material suppliers involves a multi-faceted approach. Combining reputation checks, quality control evaluation, delivery performance review, technical support assessment, and transparent pricing analysis allows your business to identify the best partners. Choosing non woven material suppliers with strong commitment to consistency and customer collaboration ultimately supports your brand’s quality standards and operational success.

- Building a Long-Term Partnership with Your Non-Woven Material Supplier

In the highly competitive and constantly evolving landscape of non-woven materials, establishing a long-term partnership with your non-woven material suppliers is not merely a business transaction but a strategic alliance that can drive sustained growth, innovation, and competitive advantage. Choosing the best partner from among top non-woven material suppliers provides more than just a reliable source of raw materials—it sets the foundation for collaboration that supports quality assurance, innovation, supply chain resilience, and business scalability.

The first critical element in building a lasting partnership with your non-woven material supplier is **mutual trust and transparency**. Non-woven materials are integral components in many industries ranging from medical to automotive, and quality variances can significantly impact product performance. Establishing clear communication channels where both parties openly share forecasts, production capabilities, challenges, and expectations ensures that you can proactively address issues before they affect the supply chain. This transparency also fosters trust, which allows suppliers to invest in your business by allocating raw materials preferentially during periods of high demand or supply constraints.

**Consistency and quality control** form the backbone of any fruitful long-term relationship. Leading non-woven material suppliers implement stringent quality management systems to guarantee that materials meet specific standards and comply with regulatory requirements. Building a partnership ensures that your supplier understands your unique specifications deeply and collaborates on continuous improvement initiatives. Over time, this commitment to quality reduces the risk of defective materials, product recalls, and delays, providing a dependable backbone for your manufacturing or production processes.

Another angle to consider is **innovation and technological advancement**. The non-woven materials industry is rapidly advancing, with suppliers investing in new processes, sustainable materials, and enhanced performance features. Partnering long-term with your supplier opens doors to co-development opportunities where your company’s needs influence the supplier’s R&D focus. For instance, if you require biodegradable non-woven fabrics or materials with improved strength-to-weight ratios, a trusted supplier is more likely to work closely with you to customize solutions that keep you ahead of competitors. This collaborative innovation cycle benefits both parties and can lead to breakthroughs that define market leadership.

**Supply chain reliability** is crucial, especially in industries where downtime or shortages can cause severe financial losses. Developing a partnership ensures that your non-woven material supplier prioritizes your orders and can effectively plan capacity to meet your demand. This often extends beyond simple delivery schedules to include strategic inventory management, risk mitigation plans, and flexibility in handling last-minute changes or emergencies. Long-term cooperation encourages suppliers to invest in infrastructure and contingency plans that benefit your business continuity.

From a financial perspective, long-term partnerships can unlock better pricing and payment terms. Rather than viewing non-woven material suppliers as mere vendors, treating them as partners may lead to volume discounts, favorable credit arrangements, and shared costs of development or logistics. Over time, this financial collaboration can improve your company’s cash flow and reduce procurement expenses, directly impacting your bottom line.

Sustainability efforts are gaining unprecedented importance in supply chain decisions, and this is especially true for non-woven materials, which often involve synthetic or disposable products. Forming a long-term partnership with suppliers who prioritize eco-friendly raw materials, recycling processes, and certifications related to environmental standards can greatly enhance your company’s corporate responsibility goals. As customer demand grows for sustainable products, suppliers aligned with these values become indispensable allies.

Finally, the relationship aspect itself—built on regular dialogue, joint problem-solving, and shared goals—cultivates a partnership that thrives on cooperation rather than confrontation. Many of the top non-woven material suppliers advocate relationship management approaches that include dedicated account managers, regular business reviews, and collaborative planning sessions. These practices ensure that both parties stay aligned as market conditions evolve, minimizing surprises and maximizing mutual benefits.

In conclusion, building a long-term partnership with your non-woven material suppliers transcends typical procurement strategies. It is a continuous process of nurturing trust, driving quality, fostering innovation, enhancing supply chain robustness, enabling financial advantages, and aligning sustainability values. By carefully selecting and investing in the right non-woven material supplier, your business gains a powerful partner capable of supporting your vision and adapting alongside your growth and challenges.

Conclusion

Certainly! Here’s an engaging concluding paragraph for your article titled “Top Non-Woven Material Suppliers: Choosing the Best Partner for Your Business,” incorporating a comprehensive perspective:

---

In conclusion, selecting the right non-woven material supplier is more than just a transaction—it’s a strategic partnership that can significantly influence your business’s quality, efficiency, and innovation capacity. By carefully evaluating suppliers based on product quality, reliability, sustainability practices, and customer support, you ensure that your business remains competitive and responsive to market demands. Remember, the ideal supplier not only meets your current needs but also grows alongside you, offering flexibility and expertise that drive long-term success. Ultimately, investing time in choosing the best partner lays a solid foundation for your business’s future, turning supply chain challenges into opportunities for growth and differentiation.

---

Let me know if you want it tailored more toward any specific perspective!